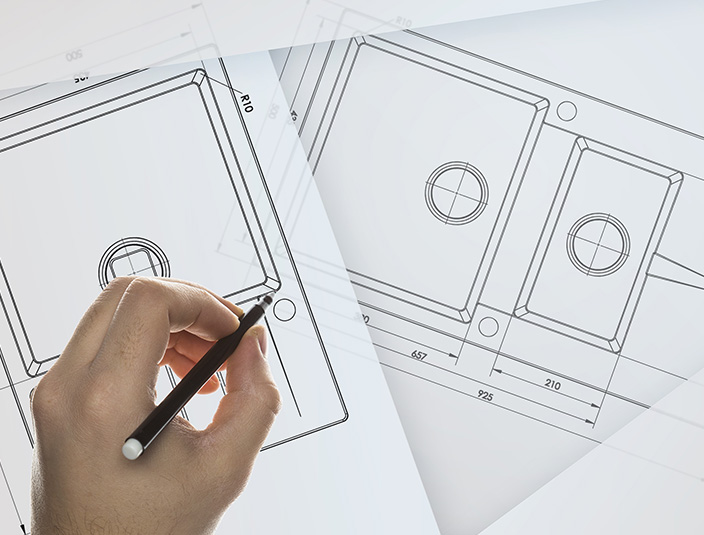

Produkcja zlewozmywaków granitowych na miarę Twojego biznesu

Nasze zlewozmywaki granitowe na zamówienie to gwarancja ponadprzeciętnej trwałości i elegancji. Produkty są odporne na zarysowania, uderzenia, przebarwienia i temperatury do 250°C. Z Kuchinox możliwa jest produkcja zlewozmywaków 1-komorowych, 1,5-komorowych oraz 2-komorowych o niemal nieograniczonej kolorystyce i kształcie.

Wybierz model z ociekaczem, półociekaczem lub bez. Fabrycznie wycięte otwory na baterię, przelew w komorze, wyjście na zmywarkę czy rodzaj korka to tylko niektóre z dodatkowych funkcjonalności oferowanych przez nas zlewozmywaków granitowych.